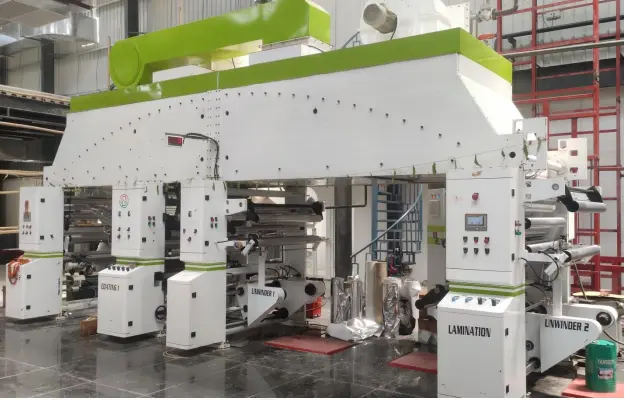

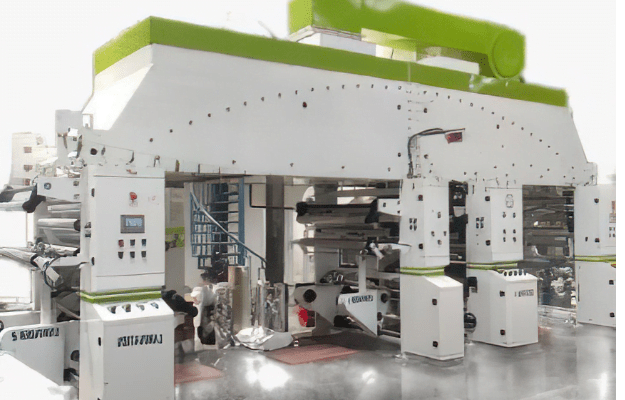

Dry Cum Wet Lamination Machine

The Niswa DRY CUM WET LAMINATOR-URANUS-DW is a result of state of-the-art manufacturing design incorporating the high end feature that are demanded by the premium end of the market. It designs to run at 350mpm, the machine is design to keep pace with the growing need on food and beverage packaging Market.

Niswa Dry Cum Wet Lamination Machine can handle wide range of Solventbase Lamination, water base, Wet Lamination and coating job. Due to its efficient design and versatile Motors and Automation System.

Niswa Dry Cum wet Laminator URANUS-DW consist of two coating unit & a lamination unit join together by drying tunnel along with short drying tunnel

Dry Cum Wet Lamination M/c Uranas 300-350

| Niswa Dry Cum Wet Lmn. Machine | Unit | Uranas-DW |

| Mechanical Speed | Mpm | 300-350 |

| Maximum Web Width | mm | 1320/1020 |

Unwind and Rewind Dia | mm | 1000 |

| Web Guid system | Ultrasonic Edge guide Sensor controlled by A.C. digital drive | |

| Maximum roll dia | mm | 1000 |

| Inside core dia | mm | 76/52 |

| Direction Unwinding/Rewinding | Under/Over |

Dry Cum Wet Lamination M/c Uranas 200

| Niswa Dry Cum Wet Lmn. Machine | Unit | Uranas-DW |

| Mechanical Speed | Mpm | 200-250 |

| Maximum Web Width | mm | 1320/1020 |

Unwind and Rewind Dia | mm | 800/1000 |

| Web Guid system | Ultrasonic Edge guide Sensor controlled by A.C. digital drive | |

| Maximum roll dia | mm | 800/1000 (Optional) |

| Inside core dia | mm | 76/52 |

| Direction Unwinding/Rewinding | Under/Over |

Description

1. Dry Lamination:

- Involves applying a thin layer of dry adhesive onto one substrate using methods such as rollers or sprayers. The dry adhesive may be in the form of a film, powder, or pre-applied coating.

2. Wet Lamination:

- Involves applying a liquid adhesive onto the other substrate surface using methods such as rollers or sprayers. The liquid adhesive is typically a solvent-based or water-based adhesive.

3. Combination Process:

- The two substrates, one with dry adhesive and the other with liquid adhesive, are brought together and passed through pressure and heat rollers. This activates the adhesives, causing them to bond with the substrates.

5. Enhanced Bonding Strength:

- By combining both dry and wet adhesive application methods, dry cum wet lamination ensures superior bonding strength between the substrates, even for challenging materials.

4. Versatility:

- Dry cum wet lamination is suitable for laminating a wide range of substrates including paper, film, foil, and non-woven materials.

6. Improved Product Performance:

- The lamination process enhances the properties of the laminated materials, such as barrier properties, strength, durability, and appearance.

7. Customization Options:

- Dry cum wet lamination can be tailored to meet specific application requirements, including adhesive type, thickness, and lamination speed.

8. Wide Range of Applications

- Dry cum wet lamination is widely used in industries such as packaging, printing, labeling, flexible packaging, and specialty applications where high-performance laminated materials are required.

Material Handled

Flexible Films: Polyethylene (PE), polypropylene (PP), polyester (PET), nylon, and other plastic films used in flexible packaging.

Paper: Various grades of paper including coated, uncoated, kraft, and specialty papers used in packaging, labels, and printing applications.

Foils: Thin metal foils such as aluminum and copper commonly used in packaging, labels, and decorative applications.

Laminates: Multi-layered materials combining different substrates, such as paper-aluminum laminates or plastic-foil laminates used in flexible packaging.

Carton Board: Solid cardboard and paperboard used in folding cartons, packaging, and printing applications.

Textiles: Fabric materials used for packaging, labels, and decorative purposes.

Labels: Self-adhesive labels made from paper or synthetic materials used in product labeling and packaging.

Non-Woven Fabrics: Textile-like materials made from fibers bonded together, commonly used in hygiene products, medical packaging, and industrial applications.

Flexible Packaging: Various types of pouches, bags, and wrappers made from flexible films and laminates for food, beverage, and consumer goods packaging.

Decorative Materials: Specialty materials like wallpaper, gift wrap, and decorative foils used for aesthetic purposes.